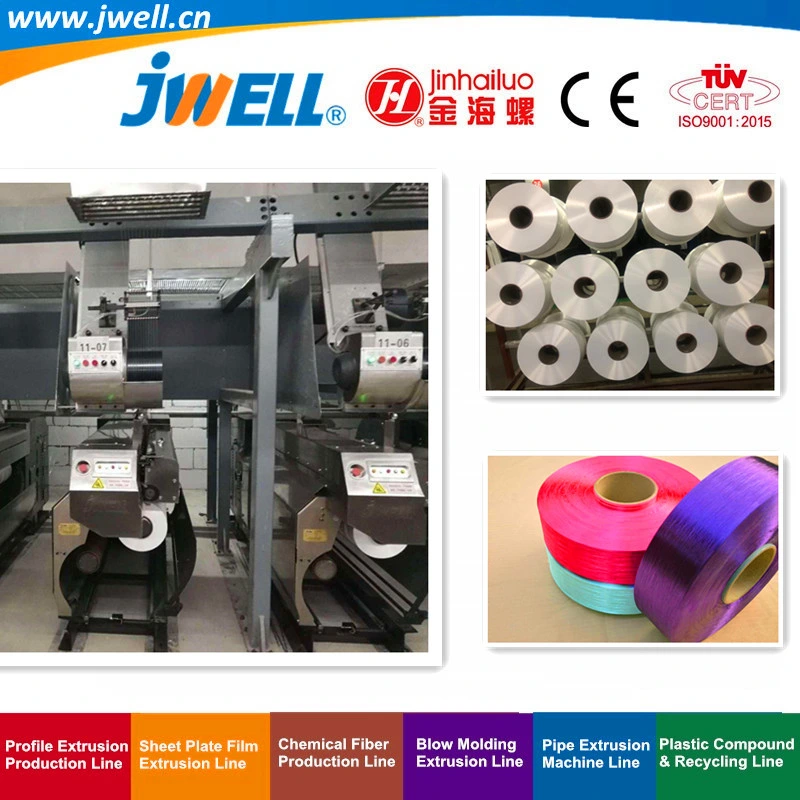

Jwell PA6/PA66 (nylon) POY/FDY Chemical Fiber/Yarn Spinning Equipment

Jwell PA6/PA66 (nylon) POY/FDY Chemical Fiber/Yarn Spinning Equipment New Products Introduction: T400 New process techno;

Basic Info

| Model NO. | Yarn Spinning Machine |

| Customized | Customized |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Type | Synthetic Fiber Machine |

| Certification | CE, ISO9001: 2000 |

| Condition | New |

| Production | POY/ FDY/Bcf/Industry Yarn/ Micro Denier (Customiz |

| Material | Pet/ PA6 / PA66 / Spandex / PP Chips, Pet Flakes |

| Application | Yarn Spinning/ Chemical Fiber |

| Dimension | Layout Drawing Will Be Provided |

| Power | 380V |

| Screw Design | Single-Screw |

| Screw and Barrel | Jinhailuo Since 1978 |

| Extruder | Jwm20/25-Jwm200/25 |

| Automatic Winder | Jwa1500 |

| After Sale Service | Yes |

| Control | PLC HMI |

| Waranty Time | 1 Year |

| Transport Package | PE Foam and Pallet Packing |

| Specification | 50-500D |

| Trademark | JWELL |

| Origin | Shanghai, China |

| Production Capacity | 1-500t |

Product Description

Jwell PA6/PA66 (nylon) POY/FDY Chemical Fiber/Yarn Spinning EquipmentNew Products Introduction:

T400 New process technology

Fully automatic high-speed precision control Winder

Special Extruder for modified chips

Interconnected control system

Hot Roller System for differential spinning

Product Overview:

Direct Spinning

PET (polyester)- POY/FDY

PA6(nylon)- POY/FDY

PET Recycling-POY Bottle flakes

PP (polypropylene) FDY/BCF

Spandex yarn

Industry Yarn

T400/T8/ITY/SPH Bi-component

PET/PA6 Multi-composite spinning

Microdenier POY

BCF line

Old Spinning project Modification

Product Description:

| Material | PET/ PA6 / PA66 / spandex / PP chips, PET flakes |

| Denier(D) Range | 50D-500D (customized) |

| NO. OF Holes (filament) | 24F 36F 48F 72F 96F 144F 228F 288F(customized) |

| Production | POY/ FDY/BCF/Industry Yarn/ Micro denier (customized) |

| Process speed | PET POY:2800-3500m/min PET FDY:2600-4500m/min |

| NO. of Positions | 6 / 8 /10 / 12 positions(customized) |

| NO. of ENDS | 8 /10 / 12 ends(customized) |

| Winders | Automatic |

| Grade class rate | up to grade class rate ≥98%,first class rate ≥95%,full package rate≥90% |

Yarn Spinning/Chemical fiber Production Equipment list:

Applications

Company Information:Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo after hundreds time of testing. After more than 35 years development, JWELL is one of the biggest extrusion machine supplier in China with 5 factories, 300 design & test engineer, 3000 employee located in Zhoushan, Shanghai, Taicang, Dongguan, Liyang. Jwel have already provided more than 500 lines located in all countries. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and available forever.

Main products: various plastic pipes extrusion lines including large diameter PE/PVC double wall corrugated pipe extrusion line, large diameter PE/PVC solid wall pipe extrusion line, PP-R/PEX/PE-RT cool/hot water pipe extrusion line, PA/PE/PVC single wall corrugated pipe extrusion line; various plastic profile extrusion lines; various plastic plate & sheet extrusion lines; chemical fiber spinning; microcomputer controlled automatic blow molding machines; plastic auxiliary recycling lines; various single & twin screw and barrel extruders; T die; screen exchangers; Rollers and Robots.

All Key parts: screw & barrel, mould, calibrator and downstream equipment are made by Jwell factory!

We only choose qualified supplier

Jwell machining workshop

Assemble workshop

Jwell factories

FAQQ1. Is Jwell Machinery Manufacturer?

A1: Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development, JWELL is one of the biggest extrusion machine suppliers in China with 300 design & test engineer, 3000 employees. We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China. Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Q2: How many brands does Jwell Machinery own?

A2: Jwell Machinery owns more than 20 subsidiaries, China famous brand JINHAILUO, JWELL, BKWELL, DYUN are our Trade Marks.

Q3: If we don't find what we need from your website, What should we do? Do you make extrusion lines as per customers' specific requirement?

A3: Yes, we can provide bespoke service to customers with specific requirements. You can send the detailed requirements by email. We will check if we can develop them. We develop new machinery every month, and some of them may not yet be updated on our website.

Q4: How do you ensure your machinery and service quality?

A4: Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, NC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Q5: How can I order and make payments?

A5: Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

Q6: If we find your bank account or email different as before, how should we respond?

A6: Please don't send the payment and double check with us before arrange payment (Bank details will be listed in every piece of proforma invoice.)

Q7: How long is the delivery date?

A7: Usually it takes about 1 - 4 months depends on different machinery upon receipt of order advance payment.

Q8: What is your Minimum Order Quantity?

A8: One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

Q9: What is your production capacity?

A9: We produce more than 2000 advanced extrusion lines every year world wide.

A10: What about shipping?

Q10: We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Q11: Is there any pre-after sale service?

A11: Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling worldwide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

Q12: Are our business& money safe with Jwell Machinery?

A12: Yes, your business is safe and your money is safe. If you check China company blacklist, you will see that it is not contain our name as we never crook our customer before. JWELL enjoys high reputation from the customers and our business and customers grows year by year.

Suzhou Jwell Poly Engineering Add: DongLin Industrial Park Chengxiang Taicang Suzhou China 215400Contact: Ms. Lily Xu (Sales Manager)

+86 158 0622 5887 Web:jwellmachinery.en.made-in-china.com

Jwell PA6/PA66 (nylon) POY/FDY Chemical Fiber/Yarn Spinning Equipment

You may also like

Send inquiry

Send now