Horizontal Ribbon Mixer Ribbon Blender Double Helix Mixer Equipment for Food Chemical Powder

Basic Info

| Model NO. | LHY |

| Certification | CE, ISO |

| Application Area | Chemical |

| Layout Type | Horizontal |

| Mixing Drum Shape | Circular Groove |

| Additional Capabilities | Drying, Coating, Cooling and Heating |

| Operating type | Continuous Operating |

| Condition | New |

| Size | Manufacturing by Client′s Requirement |

| Transport Package | Wooden Case or as Required |

| Specification | CE, ISO 9001 |

| Trademark | SL |

| Origin | China |

| Production Capacity | TBA |

Product Description

Horizontal Ribbon Mixer Ribbon Blender Double Helix mixer Equipment for food chemical powderWorking principles:Horizontal ribbon mixer is one kind of single shaft mixer of high efficiency, wide application.Horizontal, single shaft with double proportioned ribbon is housed in the tubular mixing drum. The vortex ribbon rotates with main shaft and thus bring raw material move towards direction of vortex ribbon. Outer ribbon push material from two ends to center and inner ribbon push material from center to two ends, and thus convection mixing is achieved.Horizontal paddle mixer is equipped with systematic paddles, with one circle of main shaft rotation; two systematic paddles will push materials to different directions.There is outlet at bottom of mixer, vortex structure of outer ribbon and main shaft rotation push material from two ends to center, so no leftover will be stayed in mixer tank after discharge.

Application:Powder-Powder, Powder-Grain, Powder-Liquid, Grain-Grain etc.

1.Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different

material can also be used in combination. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer

2.The driven unit

Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor. Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer.

Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

3.High efficiency mixing unitDifferent main shaft agitators can be equipped according to the properties of raw materials.The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

4.Excellent discharging unit

The drive types of valve are Manual, pneumatic, and electric.Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

5.Various inlets Various inlets on the top cover of the barrel can be designed according to different situations.They can be used as man hole, cleaning door, feeding hole, vent, and dust colleting hole.

The top cover can be designed as fully-opened lid for easy cleaning.

6.Powerful auxiliary components

Mixer is frequently equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket

sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on.

Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree.

| Model | Power | Speed | working capacity/ Batch | Dimension | mixer weight |

| (kw) | (rpm) | (kg) | (mm) | (kg) | |

| LHY-0.1 | 3 | 41 | 40-60 | 1190×740×770 | 330 |

| LHY-0.3 | 4 | 41 | 120-180 | 2300×680×1060 | 550 |

| LHY-0.5 | 5.5 | 41 | 200-300 | 2900×780×1240 | 900 |

| LHY-1 | 11 | 33 | 400-600 | 3200×1000×1400 | 1600 |

| LHY-2 | 15 | 33 | 800-1200 | 3860×1200×1650 | 2700 |

| LHY-3 | 18.5 | 33 | 1200-1800 | 4320×1300×1900 | 3600 |

| LHY-4 | 22 | 27 | 1600-2400 | 4600×1400×2000 | 4200 |

| LHY-5 | 30 | 27 | 2000-3000 | 4850×1500×2020 | 5100 |

| LHY-6 | 37 | 27 | 2400-3600 | 5400×1560×2200 | 5600 |

| LHY-8 | 45 | 22 | 3200-4800 | 5100×1720×2420 | 6500 |

| LHY-10 | 45 | 22 | 4000-6000 | 5610×1750×2360 | 7800 |

| LHY-15 | 55 | 14 | 6000-9000 | 5820×2000×2900 | 11000 |

| LHY-20 | 75 | 14 | 8000-12000 | 6060×2630×3160 | 13000 |

| Not all products are listed . For more , please contact with the sales engineering. | |||||

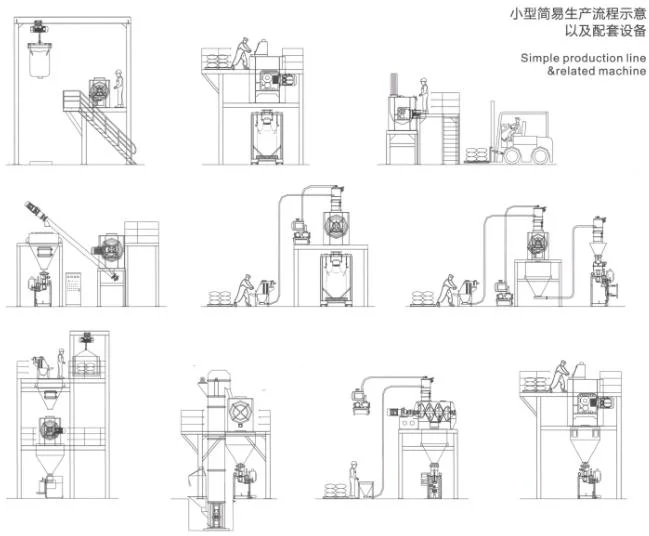

The production blending line is like:

Feeding machine: manual feeding, crane big bag feeding, screw conveyor feeding, vacuum feeding, bucket elevator etc.

Mixing machine: doubel ribbon blender, single shaft mixer, mixing machine etc.

Filling machine: storage silo, screw conveyor, packing machine, big bag etc.

Simple system as dry ingredient bulk production mixing line like:

Shanghai Shengli specializes in mixing equipment research, design, manufacture, sales and service. In past 26 years, we go deeply mixing processing filed and related technology, devote to research different kinds of mixer, modify and perfect existing mixing system, and develop new-type mixer equipment

Under working experience, we developed mixer processing machinery independently. With modern processing method, strict product management, high quality ,and professional service team, Shengli is becoming the preferred brand. We will keep researching new technology, solving mixing problems, providing more suitable mixer, promoting upgrades, and creating maximum value for customers.