Jinan Microbrewery Beer Machines 500L Wine Making Machine Equipment

Basic Info

| Model NO. | CJ-500 |

| Processing Material | Wheat, Malt, Barley |

| Process | Ferment |

| Polishing | Less Than 0.4 μm |

| Dimension | Customized |

| Power | 15-72 Kw |

| Insulation | 50-100 Polyurethane |

| Combination Method | Mash/Lauter Tun, Kettle/Whirlpool Tank |

| Water Consumption | 3.5m3/T |

| Heating Way | Electric Heating/Steam Heating/Direct Fire Heating |

| Control System | PLC |

| Degree of Automation | Semi-Automatic/Fully Automatic |

| Washing | 360 Degree Spray Ball |

| Manway | Top or Side |

| Application | Restaurants, Bars, Hotels, Brewery |

| out Size | Custom Made |

| Certification | CE ISO UL |

| Transport Package | Wooden Case or Steel Frame |

| Specification | 100L~3000L |

| Trademark | CHENJI |

| Origin | Jinan, China |

| HS Code | 8438400000 |

| Production Capacity | 500 Sets Per Year |

Product Description

1.OverviewJINAN Microbrewery Beer Machines 500L Wine Making Machine EquipmentJINAN Microbrewery Beer Machines 500L Wine Making Machine Equipment

The technology of the CHENJI brewery ensures the efficient and gentle production of wort without compromising the quality of the beer. Our system provides great flexibility in the production of various beers.

| Equipment Request | Components |

| 1. Milling System | Malt Miller |

| 2. Mashing System | Mash/Lauter Tun |

| Boiler Tank | |

| Boiler | |

| Heat Exchanger | |

| Wort Pump | |

| Stiring Device (Optional) | |

| Other accessories are available: 1. Ornamental Pipe; 2. Mashing Pipeline; 3. Operating Plateform; 4. Yeast Feeder; 5. Venturi Tube; 6. Butterfly Valve DN40; 7. Butterfly Valve DN32; 8. Soft Pipe; 9. Dregs Rake; 10. Sugar Measuring Cylinder; 11. Saccharimeter; | |

| 3. Fermenting System | Fermentation Tank |

| Other accessories are available: 1. L-Pipe; 2. Butterfly Valve; 3. Pressure Gage; 4. Solenoid Valve; 5. Vacuum Valve; 6. Cooling Pipe; 7. Thermal Insulation Pipe; | |

| 4. Cooling System | Ice Water Tank |

| Refrigeration Machine | |

| Centrifugal Pump | |

| Evaporator | |

| Ice Water Pump | |

| Relative Pipes and Valves | |

| 5. CIP System | Washing Tank |

| Sterilization Tank | |

| Pump and Valve | |

| 6. Filter System | Kieselguhr Filter |

| Membrane Filter | |

| Filtered Beer Tanks | |

| 7. Packing System | Fresh Keg Packing Machine |

| Pop Can Packing Machine | |

| Glass Bottle Packing Machine | |

| 8. Controlling System | Mashing Control Panel |

| Fermenting Control Panel | |

| Refrigerating Control Panel |

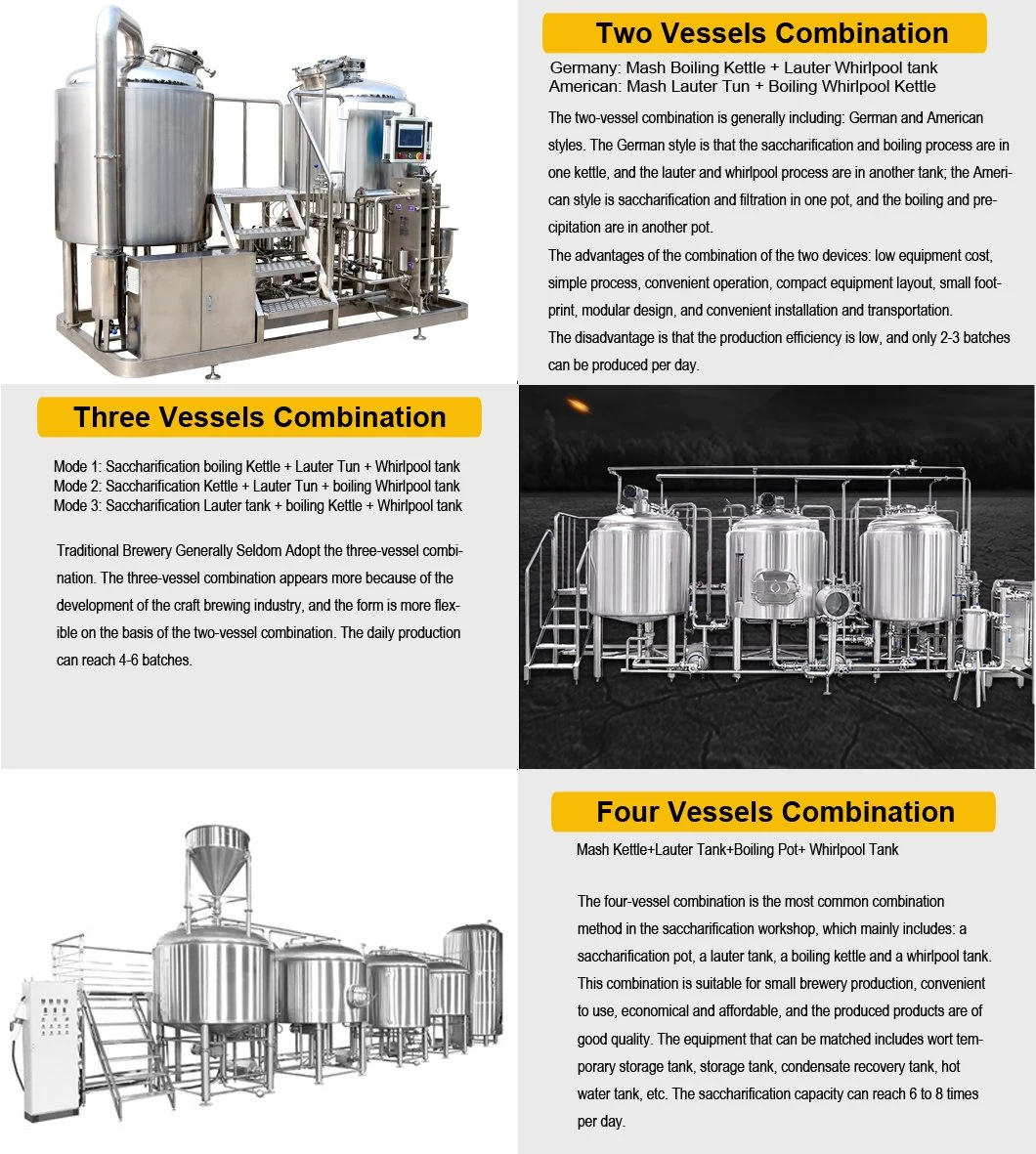

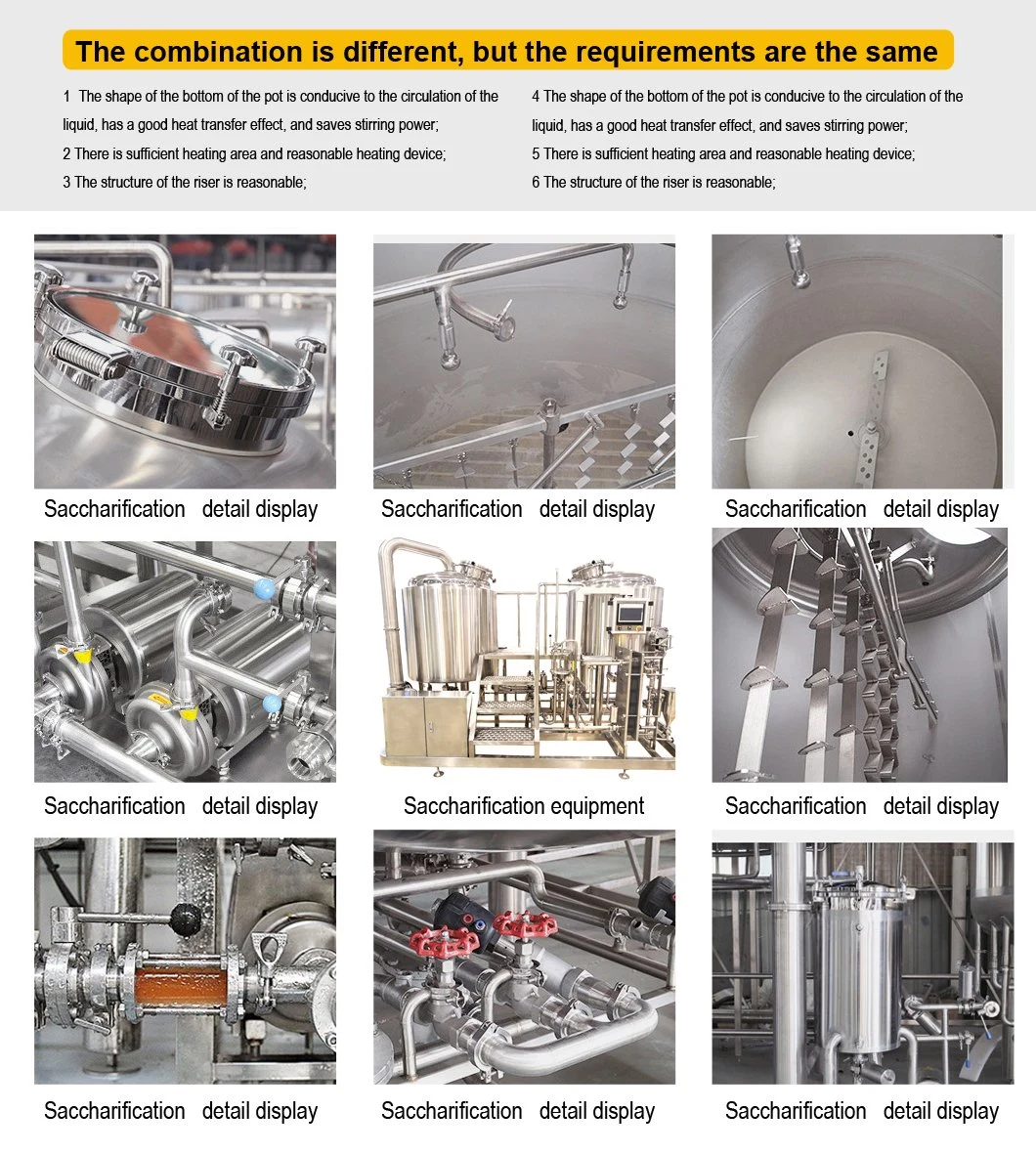

3.Malt Saccharification System

| Products Name | 1000L Ale and Lager Brewery Fermentation Tanks/Beer Brewery Equipment |

| Capacity | 1000L |

| Heating method | Steam/Direct fire (jet burner/gas burner) |

| Structure | 2-vessel: Mash/lauter tank+Kettle/whirlpool tank |

| Combi Vessel: Lauter(upper)/whirlpool (down)+Kettle Hot liquor tank at customer's request | |

| Usage | Commercial Brewery/Brew pubs/restaurant/hotel/Beer Bar |

| Exterior | SS or Copper, thickness 2.0mm |

| Interior | Stainless steel, thickness 3.0mm |

| Insulation | polyurethane, thickness 80mm |

| Cleaning | CIP arm, 360° spray ball |

| Temperature | High accuracy temperature sensor, PT100 |

| Cooling | High efficiency plate heat exchanger |

| Control | Semi-auto/auto control cabinet |

| Wort ventilate | Sanitary wort aeration device with sight glass and carbon stone |

| Milling V-wire false bottom With lauter rakes, VFD control Side spent grain manhole Stainless steel top manhole With tangent whirlpool inlet Efficient centrifugal wort pump/hot liquor pump With hops filter for trub collection Stainless steel plate heat exchanger for wort cooling Oxigenate with carbon stone Sanitary stainless steel butterfly valves and pipeline connection Stainless steel heavy duty supporting legs Argon gas protection welding, well polishing Electric heated: heating elements Steam heated: steam jacket Direct fire: firebox Items for Optional: -Agitator in kettle/whirlpool -Hydrator -Wort collector -Grant -Balance tank (sight glass type) -Steam generator, electric/gas/diesel | |

Fermentation TankUtilizing state of the art design and manufacturing, CJ provides a durable, high-quality unitank fermenter. With the use of polyurethane insulator in the interior of the tank, mirror-polished inner surface, and cooling jacket, our fermenting tanks will provide a superior products for your brewery.CJ offer you many options for your tank need, including Fermenting tank, Bright tanks and Serving tanks.Custom sizing is available for all tanks, if you have limited space, certain width/height requirements, we can manufacture all tanks to your specifications.3-120BBL fermenting systemCertified 304 stainless steelCustom size and Features available.Pressure tanks with a cone-shaped bottom and dished tank lid.Working pressure in tank: 0/+1 bar, option 0/+2,5 barMade of stainless steel 304With laser welded cooling jacket(pillow plate)Equipped with a CIP (Clean in a place) tube and a cleaning headThe materials used and the surface finishing depend on the intended application and the customer's specifications.Insulated tanks make work more efficient and contribute to a more economical use of energy.

5.Cooling systemIce water tanks, cold water tanks, stainless steel plate heat exchangers, refrigerators, refrigeration pipelines, pipe fittings and valves and control systems, of which the refrigeration unit is the core part, and the compressor unit is refrigerated with liquid ammonia, which are respectively used for tap water heat exchange and direct fermentation , Sake cans reduce the temperature of beer. The refrigerating machine adopts imported compressor, which is safe to operate and has a low failure rate, which solves the user's worries. The system pipelines are all made of sanitary and seamless steel pipe welding and fusion. Freon runs in the pipe to cool down, and high-quality polyurethane insulation pipes are used for pipelines. Thermal insulation effectively reduces heat loss.

The refrigeration system is used to cool down the saccharified wort and fermentation. The optimized design of the refrigeration system directly determines the lower energy loss in the operation of the equipment. The refrigerator we use is safe to operate and has low failure. The ice water tank is insulated with polyurethane, and the pipeline is insulated with polyethylene, which effectively reduces cold loss. The equipment cooling system is used to cool down the saccharification wort and fermentation, and is a major energy-consuming system that composes the beer equipment. The optimized configuration of the refrigeration system directly determines the lower capacity loss during equipment operation.

The CIP cleaning system of a small brewery can be equipped with different types of cleaning systems according to the scale of the equipment. There are two modes of CIP cleaning workshop and simple disinfection device for you to choose.

1. The CIP cleaning workshop is suitable for large-scale and large-volume factories. It is generally composed of lye tank, acid tank, aseptic water tank and disinfection tank. The tank body is made of stainless steel welding. The system has the characteristics of compact structure, convenient installation and maintenance, and can effectively control the tank container. Production equipment such as pipelines and pipelines are cleaned in situ. The entire cleaning process runs in closed production equipment, tank containers and pipelines, which greatly reduces the chance of secondary pollution and has a small footprint, saves operating time and improves efficiency. ; Save labor and ensure safe operation; save water, steam and other energy, reduce the amount of detergent production equipment can achieve large-scale, high level of automation to extend the service life of production equipment.

2. Small-scale production factories can also use simple CIP disinfection devices, including alkali tanks, sterilization water tanks and sanitary cleaning pumps. This device can fix the alkali tank, sterilization water tank, cleaning pump, pipe fittings and valves on a small cart, or it can be customized for you according to the scale of the equipment. The operation is flexible and simple, and it can be used in the cleaning and disinfection of various types of small brewery equipment, so that it can achieve the characteristics of thorough disinfection and no dead ends. At the same time, the equipment can also be equipped with manual, semi-automatic and fully automatic operation according to different customer requirements.

The craft beer equipment control system is the core part of the entire brewing process, including: malt crushing, saccharification, fermentation, cooling, temperature control, pressure control, refrigeration and other important systems and the overall control of other auxiliary control systems, which can realize partial control Or comprehensive PLC automatic control.

The control system adopts the beer intelligent PLC control system and intelligent control system independently developed and patented by the company. It is composed of Siemens programmable controller PLC, industrial computer, automatic control components, power distribution cabinet, and operation console. It can also control the material flow manually on the operation console. It can be controlled automatically or manually according to customer requirements.

This system adopts the upper and lower levels of computer control, adopts the Siemens STEP7 series programmable controller that was widely used internationally in the 1990s, and combines with the high-reliability industrial computer to form a powerful control system. Industrial computer real-time display, storage, query, control or modification of each process parameter to make the entire equipment in the best state; the lower control level is composed of SIMATIC STEP7-300PLC

In this system, various signals include: liquid level switch, valve position, motor, pump and other switching signals, as well as temperature and other analog signals, all enter the PLC. The PLC automatically completes the various switches according to the program set by the process requirements. The output signal completes the control of actuators such as butterfly valves, solenoid valves, pumps, reducers, etc., and completes the technological process. The communication between the upper computer and the lower computer adopts the DIN standard PROFIBUS-DP bus, which can be easily connected with other control systems for unified management.

1

Q: Are you professional Supplier and tanks Manufacture ?

A: We are the manufacturer of beer brewing equipment for 15 Year and deal in export business since 10 years ago .2

Q:Can I have the customized products with personal design?

A:Yes,we support any of your wish design,can design and manufacture as client's requirements.3

Q: Can you guarantee your beer brewing system quality?

A: All of the equipment will be inspected before the package, appliance of the international Standard.4

Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to all client.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.5

Q: Which export port you use?

A:Commonly we will use Qingdao port, sometime, can be other port as your wish.6

Q: I am green hand in brewery industry? Could you supply training for us?

A: Yes, our engineer can supply the installation equipment and brewery training service overseas.

7

Q: what is your payment item ?

A: We accept 40%TT + 60%TT as for the balance payment before the delivery