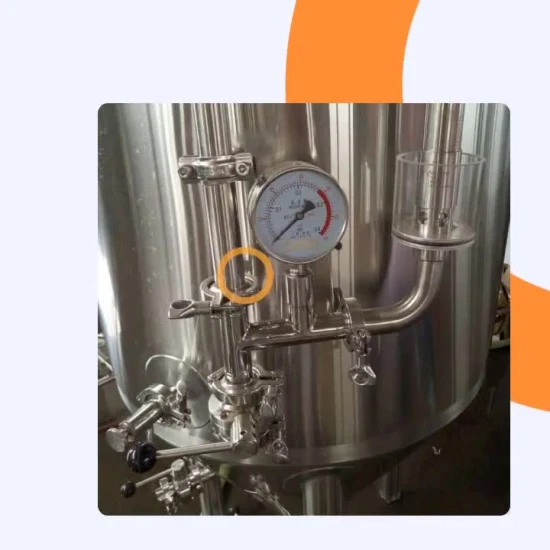

Beer Factory Beer Brewing Equipment Beer Conical Fermentation Tank

The fermentation process of dairy products and wine is an aseptic and non-polluting process. The fermentation tank adopt;

Basic Info

| Model NO. | BF |

| Processing Material | Beer |

| Process | Miller Plate |

| Transport Package | Naked Woodcase |

| Specification | 100-25000L |

| Trademark | haichuan |

| Origin | Wenzhou |

Product Description

The fermentation process of dairy products and wine is an aseptic and non-polluting process. The fermentation tank adopts an aseptic system, which avoids and prevents the pollution of microorganisms in the air, greatly prolongs the shelf life of the product and the purity of the product. Designed and installed with sterile breathing vents or sterile positive pressure fermentation systems. The tank body is provided with a Milo plate or a labyrinth jacket, which can be heated or cooled by heating or cooling medium. The capacity of the fermenter varies from 300-15000L. According to the scope of use, fermentation tanks can be divided into small laboratory fermentation tanks, pilot production fermentation tanks, large fermentation tanks, etc. Fermentation tanks are widely used in dairy products, beverages, bioengineering, pharmaceuticals, fine chemicals and other industries. The tank body and the upper and lower filling heads (or cones) are processed by spinning R angle. The inner wall of the tank is mirror-polished, and there is no hygienic dead angle. The fully enclosed design ensures that the materials are always mixed and fermented in a pollution-free state. The equipment is equipped with Air breathing holes, CIP cleaning nozzles, manholes and other devices.You may also like

Send inquiry

Send now