AISI304 Beer Brewing Equipment 1000L Steam Heating Brewhouse

Basic Info

| Model NO. | 1000L |

| Material | SS304 |

| Tank Thickness | Inner 3mm Outside :2mm |

| Temperature Control | Automatic |

| Heating | Gas Steam Generator |

| Heat Insulation | Rock Wool Th:80-100mm |

| Inner Surface | Pickled and Passivation |

| Welding | Argon Arc TIG 100% |

| Function | Boiling Wort |

| Transport Package | Steel Frame or Wooden Case |

| Specification | as customer request |

| Trademark | Zunhuang |

| Origin | China |

| Production Capacity | 500piece |

Product Description

1000L Brewery Specifications| Item | Capacity |

| Malt miller | 300-500KG/H |

| Mashing system | 1000L 2-vessel brewhouse (mash&lauter tun + boil kettle&whirlpool tank) -Hot water tank Heating method can be steam or direct fire. |

| Fermentation system | 1000L / 2000L |

| Cooling system | 3000L glycol water tank + chiller |

| Control system | PID / PLC |

| CIP cleaning system | Disinfection tank + alkali tank |

| Necessary parts | Fitting |

- Volume + ~30% headspace

- Inner-shell (SUS304L), thickness: 3.0mm;

- External-shell (SUS304L), thickness: 2.0mm;

- Insulation: Rock wool thickness: 100mm;

- Inner surface is pickled and passivated.

- Mash rakes with grain out plow

- Sparge arm; False bottom, Laser filter with 0.7mm gap;

- PT100 Temperature sensor probe;

- Spent grain manway

- Glass manhole(glass): Φ500mm;

- Balancing tank / grant

- Sparging monitoring level gauges

- CIP spray ball

- Volume + ~50% headspace

- Inner-shell (SUS304), thickness: 3.0mm;

- External-shell (SUS304), thickness: 2.0mm;

- Insulation: Rock wool,thickness: 80mm;

- Inner surface is pickled and passivated.

- Tangential port

- Level gauge

- PT100 Temperature sensor probe;

- Glass manhole(glass): Φ500mm;

- CIP spray ball

- Condensation stack valve

- Indoor exhausted device

- Volume + ~30% headspace

- Inner-shell (SUS304), thickness: 3.0mm;

- External-shell (SUS304), thickness: 2.0mm;

- Insulation: Rock wool thickness: 80mm;

- Inner surface is pickled and passivated.

- Level gauge

- PT100 Temperature sensor probe;

- Top manhole.

- Overflow pipe

- CIP spray ball

Gas steam generator:

Inner surface pickled and passivation:

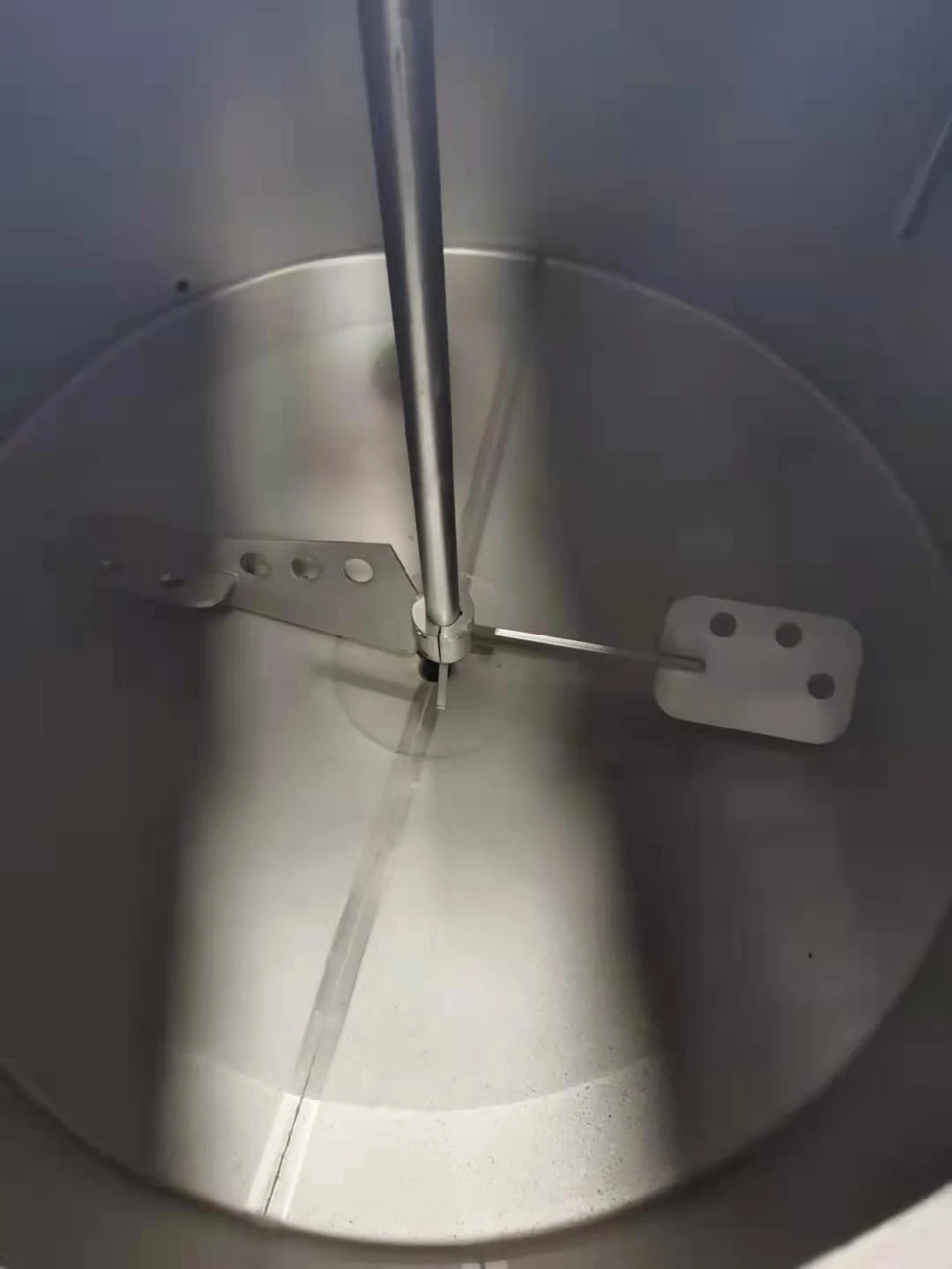

Mash tun inside with agitator:

Lauter tun inside with raker:

Fermentation tank details:

Fermenter cooling method is cooling dribbling with standard parameters, layout and control mode in domestic. Zunhuang companies design and manufacture cooling dribbling according to 0.4-0.5 meters per cubic meter cooling area. And the fermentation tank adopt two-stage cooling refrigerant control mode at the end of the cone and the tank level 10--15cm down. So such design and cooling method to control the flow of the cooling liquid state in fermentation tank by the size of the two-stage cooling refrigerant flow. It will improve heat transfer efficiency and cooling rate, faster cooling, and reduce cooling costs and high economic efficiency equipment commercial operation.

Other Auxiliary Equipment:

1.Malt crusher

2.CIP Cleaning system

3.Control cabinet

4.Cooling system includes glycol tank and chiller unit

Company information: